Testing Services

Ensuring Excellence in every product

At UK-NSI, we understand that quality is non-negotiable in electronic manufacturing. Our comprehensive test services cover Surface Mount Technology (SMT), post-assembly and final assembly, ensuring that every product meets the highest industry standards. With state of the art inspection, in-circuit testing and functional testing solutions, we provide precision, reliability, and traceability for your electronic manufacturing needs.

3D Automated Optical Inspection (AOI)

Our inline 3D AOI systems provide high speed, high accuracy inspection to ensure quality manufactured PCB assemblies. With advanced imaging and real-time defect analysis, our AOI processes ensure:

-

Component Verification: Checks for presence, correct placement, polarity and size.

-

Solder Joint Inspection: Evaluates solder volume, joint quality and detects bridging.

-

Foreign Object & Contamination Detection: Identifies foreign particles or contaminants that may impact performance.

With AOI as part of our quality control process, we reduce defects, improve first time yield and maintain superior reliability in every PCB we manufacture.

Precision & Accuracy

Automated Optical Inspection

Hidden Joint Defect Detection

X-ray Inspection

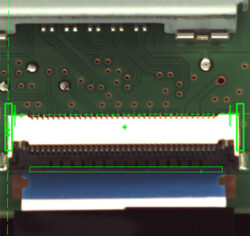

Inline X-Ray Inspection – Hidden Joint Defect Detection

For complex assemblies with hidden solder joints, Ball Grid Arrays (BGAs) and high density components, our X-ray inspection technology ensures that solder connections maintain the highest quality while meeting customer requirements.

Key benefits include:

-

Non-Destructive Testing: Identifies defects without compromising the integrity of the assembly.

-

BGA & QFN Solder Joint Analysis: Ensures reliable connections on components with concealed solder points.

-

Void & Short Detection: Eliminates the risk of electrical failure due to poor soldering.

By utilising advanced X-ray imaging, we detect potential failures before they become critical issues, ensuring long-term product reliability and manufacturing efficiency.

In-Circuit Testing (ICT)

Our In-Circuit Test (ICT) systems validate electrical performance at the component level, preventing potential defects from progressing further.

Our ICT capabilities include:

-

Short/Open Circuit Detection: Ensures proper electrical pathways.

-

Test Jet for Connector Verification: Confirms correct insertion and functionality of connectors.

-

Component Testing: Measures passive and active components for proper operation.

-

Basic Functional Testing & Boundary Scan: Verifies circuit integrity and design compliance.

ICT plays a critical role in minimising costly rework and ensuring that every unit leaving our facility performs to specification.

Comprehensive Electrical Verification

In-Circuit Testing

Ensuring Real World Performance

Functional Testing

Functional Testing

UK-NSI’s functional testing solutions go beyond standard inspections to ensure that your electronics operate exactly as intended in real-world conditions.

Our standardised base testing units include:

-

Power Supplies & Digital I/O: Simulating real-world operational environments.

-

Multiplexers & Digital Multimeters: Providing precise voltage, current and resistance measurements.

-

Automotive Communication Testing: Validating CAN, LIN, Most, and APIX communication protocols.

By conducting in-depth functional tests, we ensure that your PCBs and electronic assemblies meet the highest performance and durability standards.

In-House Test Software Development

Custom Solutions for Your Needs

Our dedicated test engineering team develops tailored software solutions to optimise testing processes and maximize efficiency. This allows us to adapt our testing capabilities to meet unique product requirements and industry specifications.

Expert Vision Inspection & Calibration

UK-NSI’s engineering team specialises in advanced vision inspection, test development and calibration, ensuring that every product meets the stringent requirements of the automotive and other electronics industries.

Our continuous improvement approach drives:

-

Consistent Quality Assurance – Identifying and correcting defects in real time.

-

Enhanced Efficiency – Optimising production cycles and reducing downtime.

-

Customer Specification Compliance – Meeting and exceeding your quality expectations.

Quality Assurance

Inspection & Calibration

Why Choose UK-NSI for Your Testing & Inspection Needs?

-

Industry Leading Technology – Cutting edge AOI, X-ray, ICT, and functional testing.

-

Automated, High Precision Processes – Ensuring reliability and repeatability.

-

In-House Expertise – Dedicated test engineers with extensive industry knowledge.

-

Proven Track Record – Meeting stringent automotive and electronic manufacturing standards.

Partner with UK-NSI for Uncompromising Quality

When precision, reliability and quality matter, UK-NSI is your trusted partner in surface test and inspection solutions. Contact us today to discuss how our advanced testing services can enhance the performance, reliability and longevity of your electronic products.

👉 Get in touch with our experts today! Let’s build quality together.