POST Assembly

At UK-NSI, Post Assembly is a critical phase in our end-to-end electronics manufacturing process, ensuring that every assembled product meets the highest standards of quality, durability, and performance before delivery. Our facility is designed to handle complex post assembly requirements, integrating automated handling, conformal coating, depaneling, optical inspection and functional testing to deliver high quality results.

With over 35 years of expertise, UK-NSI has established itself as a trusted partner in contract electronics manufacturing, providing high precision assembly solutions for the automotive industry. By utilising the latest smart manufacturing technologies, automation, and rigorous quality control, we ensure that every product leaving our facility is built to withstand demanding operational environments while maintaining consistency, traceability and compliance with industry standards.

Comprehensive Assembly Services

Our Post SMT Assembly Manufacturing process ensures that every PCB leaving our facility meets the highest quality and performance standards. From advanced handling systems to precise conformal coating, automated inspection, and functional testing, we offer a fully integrated post SMT solution. Our technology, combined with our commitment to quality, traceability and efficiency, enables us to support both high volume and niche production requirements for various industries, including automotive, aerospace and consumer electronics.

Our manufacturing facility is equipped with automated handling equipment, precise application systems and testing processes to optimise production, reduce waste, and enhance product reliability.

Whether you need conformal coating for environmental protection, high-accuracy AOI inspections, precision PCB depaneling or functional testing to verify product integrity, UK-NSI’s Post Assembly services provide the expertise and technology required to deliver market leading solutions.

Precision & Quality Focused

POST SMT

Post SMT Capabilities

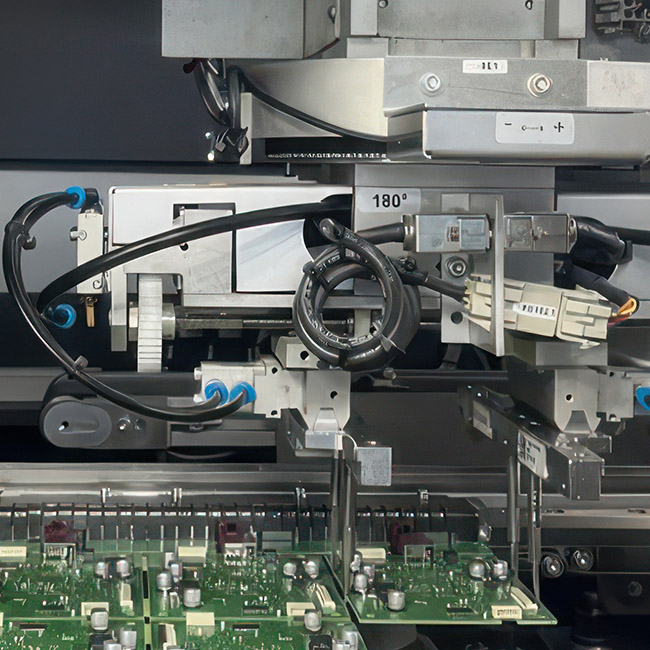

Automated PCB Handling

To maintain efficiency, precision and consistency, our Eunil Handling Equipment automates the transportation of PCBs throughout the assembly process. This minimises manual handling, reducing potential damage while ensuring streamlined production.

-

5 Rack Magazine On-Loaders, Cooling Buffers, Reject Buffers, Handling Buffers and Inverters ensure seamless PCB movement between process stages.

-

Supports PCB sizes ranging from 50mm x 50mm (L x W) to 430mm x 330mm (L x W), providing flexibility for a wide range of board designs.

-

Ensures optimised workflow, traceability and defect reduction, improving overall process efficiency.

Precision Conformal Coating Application

Protecting PCBs from moisture, dust, chemicals and extreme environmental conditions is crucial for long term reliability. UK-NSI utilises automated conformal coating systems to achieve consistent, high quality results while improving throughput.

-

2 Nordson Concoat Applicators deliver controlled, automated conformal coating, ensuring even coverage and protection against external factors.

-

One machine features SC-400 PreciseCoat Jet technology for high precision coating and a fan applicator for broader coverage.

-

The second machine is equipped with 10mm and 5mm fan applicators, providing versatility for different coating requirements.

-

Nordson Excelsius Curing Oven provides controlled and uniform curing, improving adhesion and overall coating integrity.

Automated Optical Inspection (AOI) & Quality Control

Ensuring defect free PCBs before further processing is critical to maintaining high quality standards and reducing rework costs. Our automated AOI and ACI systems perform real time inspections for ultimate quality assurance.

-

Inline Nordson ACI Inspection Machine detects coverage issues, contamination and coating defects, ensuring proper application of conformal coating.

-

Inline Yamaha AOI Inspection Machine performs detailed optical inspections, identifying component misalignment, solder joint defects and foreign object contamination.

-

Eliminates manual inspection errors, enhances traceability and ensures compliance with industry and customer specific quality standards.

PCB De-Paneling & Routing

For PCBs assembled in panels, precise depaneling is required to ensure clean separation without stressing the board or components. At UK-NSI, we use automated depaneling solutions to guarantee high quality results with minimal operator intervention.

-

2 ASYS PCB De-Panel Machines deliver accurate, repeatable routing of PCBs, ensuring a clean, damage free cut.

-

Reduces manual handling risks while improving efficiency and consistency in POST SMT processing.

Functional Testing & Verification

Every product must perform flawlessly before final assembly and shipment. Our functional test stations validate the electrical and operational integrity of assembled PCBs, detecting any potential failures before they reach the customer.

-

4 Offline Function Test Stations evaluate board performance, connectivity and component functionality under real world conditions.

-

Functional tests verify electrical parameters, power supply integrity, signal processing and communication protocols.

-

Ensures reliable product performance, reduces failures and improves overall product quality.

Why Choose UK-NSI for POST SMT Solutions?

As part of the Nippon Seiki Group, UK-NSI has a long standing reputation for delivering excellence in electronics manufacturing services (EMS). We support high-volume production and specialised manufacturing, making us the perfect partner for POST SMT solutions that demand precision, consistency and reliability.

Contact us today to discuss your manufacturing needs and discover how our expertise, technology and commitment to quality can drive success for your business.

Let’s Build Excellence Together.