Engineering Solutions

At UK-NSI, our experienced engineering team is dedicated to driving efficiency, optimising processes, and delivering high-quality manufacturing solutions. With a focus on continuous improvement, advanced problem solving, and cutting-edge technology, we ensure that our customers achieve their performance, quality, and cost objectives.

We work closely with customers to develop tailored engineering solutions that meet their specific manufacturing requirements creating robust, scalable and efficient production processes. Through continuous improvement activities working closely with production and quality teams we strive to improve on key performance indicators (KPIs) such as First Time Yield, Uptime, and Overall Equipment Effectiveness (OEE) being at the forefront of manufacturing technologies.

Engineering Capabilities

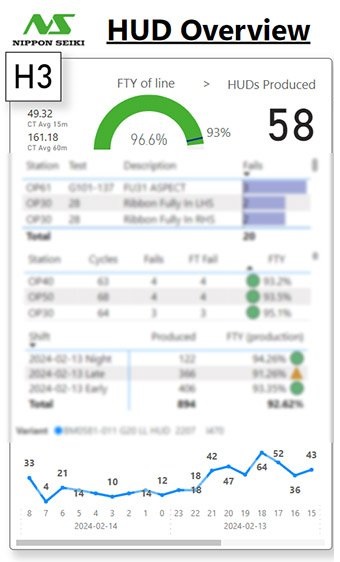

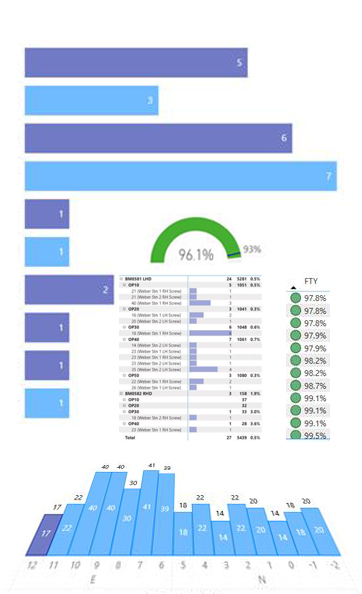

Real-Time Data Measurement & Process Monitoring

We implement advanced data measurement systems that provide instant insights into the manufacturing process, allowing for quick decision-making and proactive issue resolution.

- Live production monitoring for real-time performance tracking

- Automated data collection to reduce errors and improve efficiency

- Instant alerts & feedback loops to maintain process stability

- Data-driven decision-making for continuous operational improvements

Statistical Process Control (SPC) & Route Enforcement

To ensure consistent quality and precision, we utilise SPC techniques that monitor, control, and optimise production processes.

- Data-driven process control to identify trends and eliminate variability

- Route enforcement systems to maintain production consistency and prevent errors

- Early defect detection & correction for improved First Time Yield (FTY)

- Reduced scrap and rework, leading to significant cost savings

Continuous Improvement & Lean Manufacturing

We embrace a culture of continuous improvement (Kaizen) to enhance productivity, reduce waste, and optimize workflows.

- Lean manufacturing principles to increase efficiency and eliminate non-value-added activities

- Six Sigma methodologies to drive process excellence and defect reduction

- Cross-functional problem-solving teams to address root causes of inefficiencies

- Cost reduction strategies that maintain quality while improving profitability

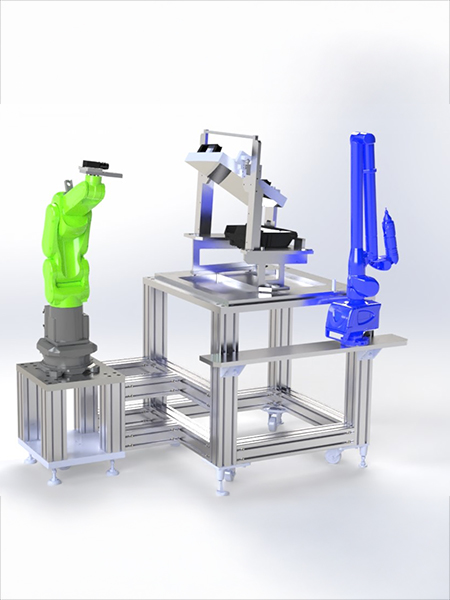

New Process Design & Industrialisation

Our team specialises in developing and implementing new manufacturing processes tailored to the specific requirements of our customers.

- Design & validation of efficient, scalable production workflows

- Seamless integration of new technologies into existing manufacturing lines

- Process automation & robotics for increased speed and precision

- Full industrialisation support to transition from prototype to mass production

New Equipment Specification & Design

At UK-NSI, we design, specify, and implement advanced manufacturing equipment that enhances precision, automation, and efficiency.

- Customised machinery and tooling solutions for optimised production

- Automation & robotics implementation to improve consistency and reduce labor costs

- State-of-the-art equipment validation to ensure reliability and compliance

- Energy-efficient machine designs to reduce operational costs

Advanced Problem-Solving & Root Cause Analysis

We use structured problem-solving methodologies to address and eliminate production challenges.

- Failure Mode & Effects Analysis (FMEA) to identify and mitigate risks

- 8D problem-solving techniques to systematically resolve defects

- Real-time defect tracking & corrective action implementation

- Continuous feedback loops to prevent recurring issues

Uptime & Efficiency Optimisation

Our engineering solutions focus on maximising equipment uptime and overall efficiency, ensuring minimal downtime and optimal production output.

- Preventive & predictive maintenance strategies to avoid unplanned stoppages

- Smart factory automation for real-time monitoring and quick response

- Process cycle time reduction to boost throughput and minimise waste

- Optimised equipment utilisation for higher productivity

Project Management & Engineering Support

We provide comprehensive project management services, ensuring smooth execution from concept to full-scale production.

- End-to-end project oversight, from planning to final implementation

- Customer collaboration to meet specific technical and operational needs

- Risk assessment & mitigation planning for a smooth production launch

- Technical support & training to empower teams with the latest innovations

Why Choose UK-NSI for Engineering Solutions?

Industry Leading Expertise – Over 35 years of experience in advanced manufacturing engineering

Customer Centric Approach – We work closely with customers to develop tailored solutions that meet their needs

Cutting-Edge Technology – Implementing the latest automation, AI-driven detection and advanced manufacturing techniques

Proven Results – Enhancing First Time Yield, Uptime, and Efficiency across various industries

Scalability & Flexibility – Solutions that adapt to low-volume prototyping and high-volume production

Let’s Build the Future Together

Partner with UK-NSI to drive innovation, efficiency, and quality in your manufacturing process. Contact us today to discuss how our engineering expertise can help bring your product to market with precision and reliability.

Start your transformation with UK-NSI today!